Our Directions

Intellectual automation of manufacturing processes

Almost all monotonous, time-consuming, and difficult tasks for humans can be robotised with a predictable economic effect, controllable technical risks and time expenditure.

PROF-IT GROUP offers efficient tools for optimising the robotisation-based operations. You can use industrial robots in a variety of industries: starting from jewellery industry to heavy metals, from assembling small parts to application of coatings.

What are cyber physical systems?

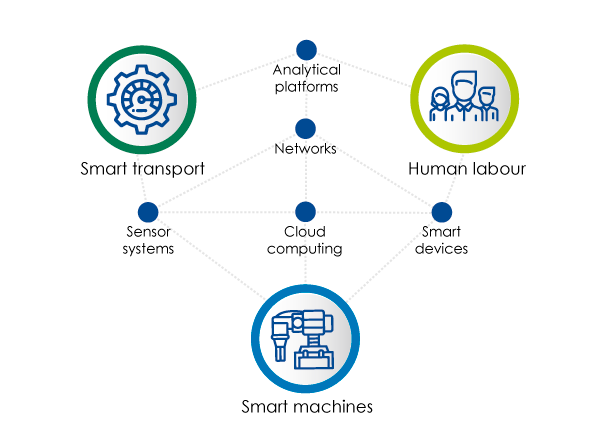

Cyber physical systems (CPS) is a complex hardware-software solution that may include stationary and mobile robots, sensor and management systems, technological equipment, peripheral equipment, security systems, operator and software interface that controls all the equipment.

Cyber physical system elements

Traditional challenges of the manufacturing landscape

High labour intensity of processes:

- t is difficult to increase productivity when increasing output plans;

- It is impossible to cut costs sharply when reducing output plans;

- Costs must be increased proportionally when increasing planned output;

- Additional costs related to working conditions organisation are inevitable;

- Direct labour costs and indirect costs related to them.

Inconsistent product quality:

- Losses related to penalties;

- Labour, time, material losses related to product rework;

- Losses resulting from irreparable defects;

- Losses related to work in progress;

- Losses related to suboptimal use of consumable materials.

Harsh working conditions:

- High injury risk, accidents, professional diseases, health hazards;

- Losses resulting from fines for violation of work safety rules;

- Losses resulted from injury risks and accidents, professional diseases.

Have you ever met these challenges? We have a solution

PROF-IT GROUP offers a comprehensive approach to robotisation of the manufacturing process. Our specialists in the area of digital industrial integration are qualified in ERP, MES, PLM, QMS, APS systems, Industrial Internet of Things (IIoT) technologies, industrial identification, etc. We will select a suitable solution for you and help you ensure maximum return on investment.

What results you can expect from using cyber physical systems?

Reduction of safety and health regulations, lower losses related to accidents, defects, suboptimal usage of materials

Solutions:

PROF-IT GROUP collaborates with leading vendors of industrial software and hardware: