Our Directions

Ensure transparent manufacturing using RFID and RTLS solutions

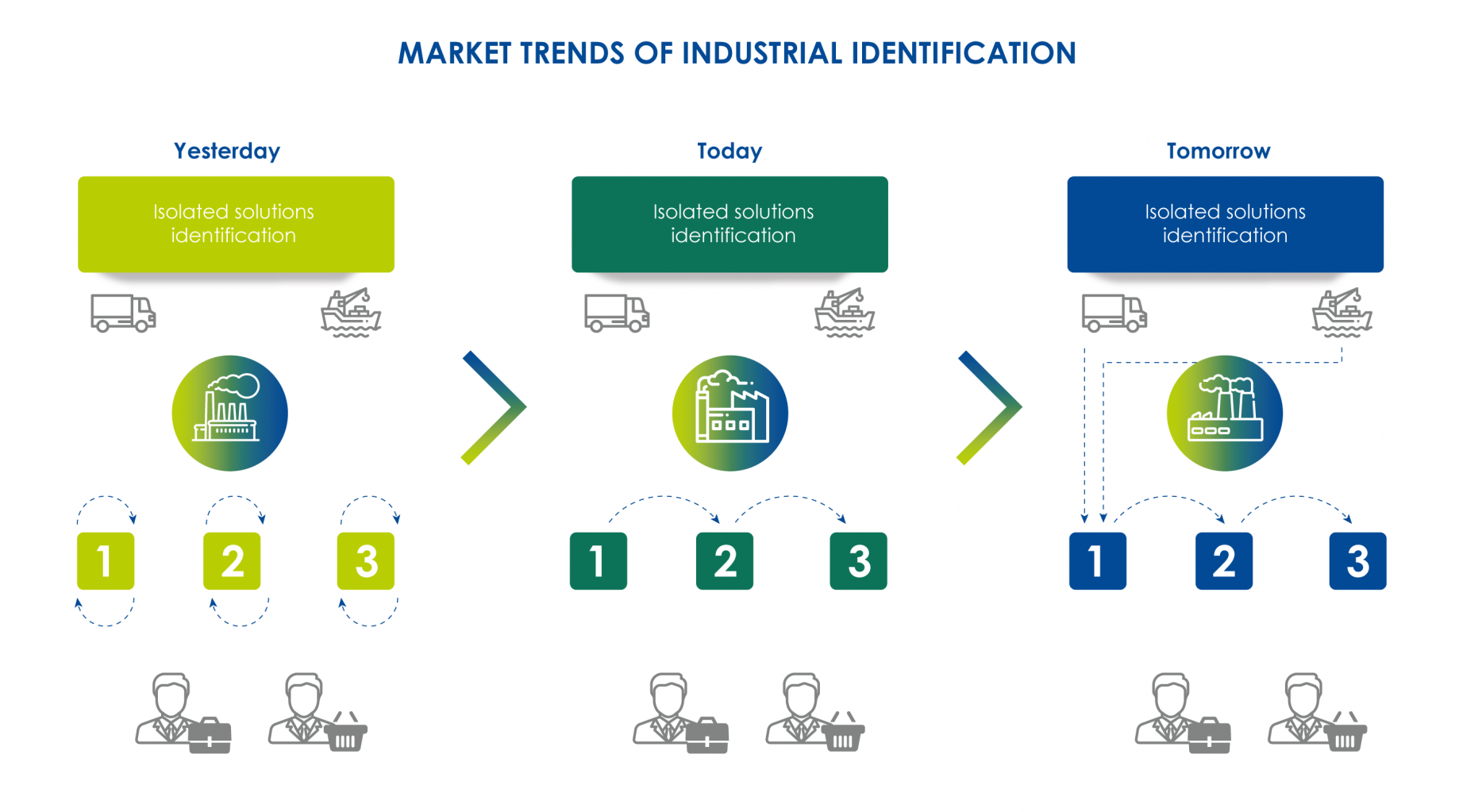

To remain competitive, meet customer expectations and comply with market trends, you must ensure transparency of the entire chain of manufacturing and sales. Industrial identification: solutions with passive labels (RFID) and active online positioning system (RTLS) make it possible to collect and process data on all strategic production areas of an enterprise.

The PROF-IT GROUP portfolio includes a wide range of solutions in the industrial identification area. We will help you choose and implement the technology that will suit the tasks of your enterprise.

Blurring the boundaries between the digital and physical worlds

Application scope of the industrial implementation

PROF-IT GROUP solutions in the area of industrial identification

Manufacturing logistics

This solution enables to automate major warehouse processes, minimise human factor impact, reduce manufacturing costs, improve the relevance of analytical data, introduce continuous control of end product and materials movement by integrating the identification subsystem with ERP/WMS.

Dispatching and monitoring

This solution helps manufacturing companies monitor movement and operating modes of equipment and parts, automatically check compliance of consumables and gear, collect asset usage statistics, and record hours in operation and location.

Product quality control

The quality control solution may be used for product authenticity checks, developing loyalty systems and customer service. Thanks to using the distributed register technology and the latest standards of radio frequency identification, the unique product identifier cannot be cloned.

Asset control and smart storage

Implementation of smart storage areas will help introduce fully automated accounting of critical assets and online monitoring of assets within controlled warehouse. You can restrict access to objects inside a controlled facility using unique electronic identifiers.

Online asset monitoring

The solution ensures precision positioning and monitoring in the online mode of employees, equipment, and other critical objects both outdoors and indoors. You can collect diagnostic indicators from equipment, environment conditions; control collisions; visualise and analyse data.

Why our customers trust us to implement RFID and RTLS

in-depth knowledge of implemented IT products and digital transformation trends

reference sites are established at a series of our customer enterprises