Our Directions

Best manufacturing management practices in a single system

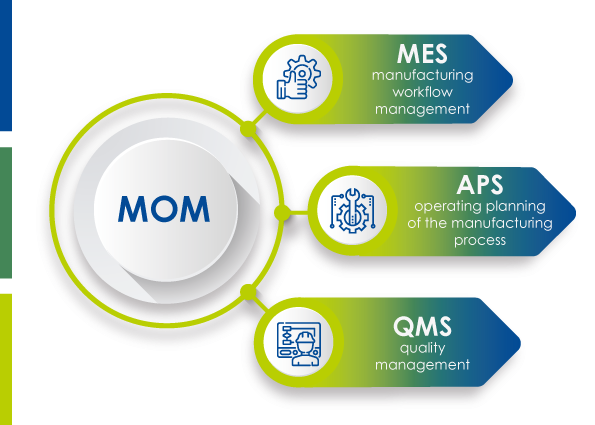

Manufacturing operations management (MOM) is an integrated solution providing full transparency of manufacturing processes. The system enables to continuously improve the operations efficiency and includes a functionality for manufacturing process management (MES - Manufacturing execution system), operating optimised planning of manufacturing (APS – Advanced planning & scheduling) and a quality management system (QMS)

MOM architecture

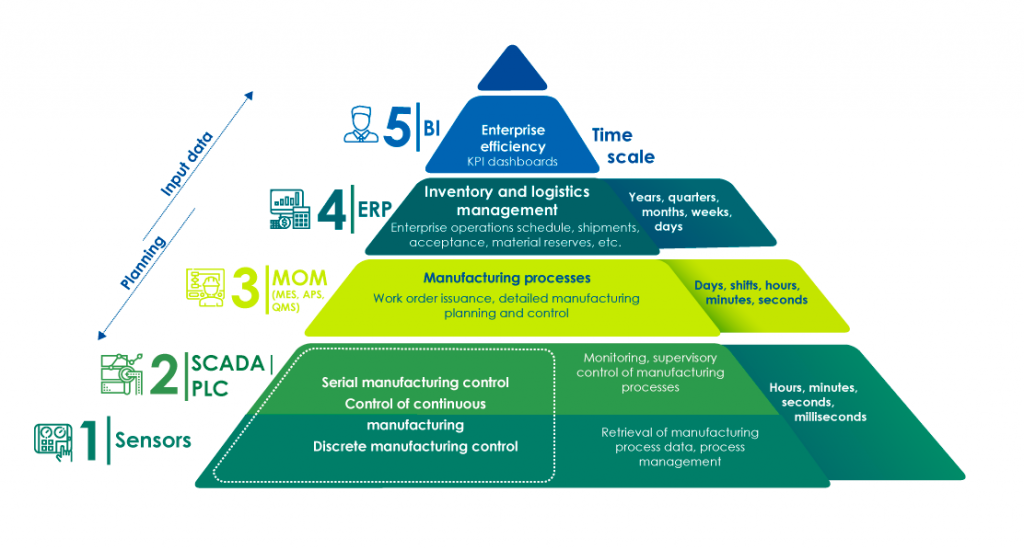

MOM within the IT structure of an enterprise

Manufacturing progress accounting using the MES system in the online mode

MES (Manufacturing execution system) ensures operating control of the manufacturing process and operation status accounting: starting from the moment of order issuance to ready product. The solution enables two-way interaction, for example, using precise and relevant data you can record production statuses of half-finished items, parts, assembly unites along the manufacturing route and automatically retrieve order fulfilment data.

Tasks solved by MES

- Manufacturing order dispatching,

- Distribution and control of resources statuses,

- HR management and coordination of collaboration,

- Coordination of technological processes,

- Documentation control,

- Productivity analysis,

- End product monitoring,

- Coordination of internal logistics and warehouse processes,

- Technical maintenance management.

Operating planning of the manufacturing process using an APS system

APS (Advanced planning & scheduling) is a solution of operative planning of the manufacturing process. The system supports creating manufacturing schedules considering the existing manufacturing limitations and peculiarities. Using APS systems, you can develop manufacturing plans based on the resources load data and existing order portfolio, as well as optimise plans based on various criteria, for example, deadlines, priorities, and corrective maintenance.

Tasks solved by APS

- Planning optimisation based on deadlines, priorities, and equipment fleet,

- Swift recalculation of a plan in case of deviations,

- Corrective maintenance optimisation,

- Estimation of order execution and shipment time frames,

- Visualisation of manufacturing flows,

- Real-time plan modification,

- Creating tasks for shifts/24-hour periods,

- Calculation of needs in materials and components.

Quality management using the QMS system

QMS (Quality management system) is a solution for quality management. The system supports compliance of the manufacturing process with the applicable standards ensuring operating control and continuous manufacturing improvement. Using the QMS, enterprises may detect manufacturing errors in a timely manner, minimise expenses related to defect elimination and avoid further processing and shipment of non-compliant products.

Tasks solved by QMS

- Incoming PPAP control,

- Online quality monitoring at all phases of the manufacturing process,

- Product quality planning,

- Measuring instrument control,

- Prevention of further movement of non-compliant products along the technological process,

- Recording non-compliances detected at quality control stations and tracking item numbers,

- Audit and claim management,

- Reduction of expenses related to item rework and warranty repairs,

- Outgoing quality control,

- Prevention of non-compliant product sales to consumers.

Suitable for companies:

We suggest such solutions as:

- PROF-IT MES

- Dassault Systems - DELMIA Apriso

- Siemens - SIMATIC IT MES

- Dassault Systems - DELMIA Ortems

- Siemens - SIMATIC IT Preactor

- PROF-IT QMS

- Dassault Systemes - Apriso - Quality

- Siemens - SIMATIC IT Unilab